Ⅰ. Batching system

1. Modular structure, reasonable layout. It is convenient to install and dismantle.

2. There are 5 m3, 8 m3, 15 m3 three kinds of batching hopper for choice, there are insulation net on top of bin which prevent large size aggregate entering.

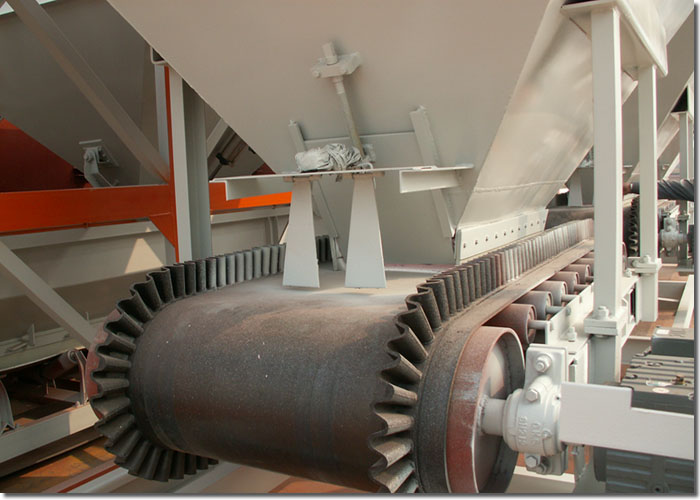

3. The belt feeder is equipped with reducing motor, with steady running, low noise and long service life.

4. All the belt use circular belt without joint, with steady running, low noise and long service life.

5. There is screen at entrance of feeding belt conveyor which can prevent large size material entering into drying drum, reduce waste and save cost.

6. The collecting belt conveyor and feeding belt conveyor use electric drum for driving with simple structure and low fault rate.

Ⅱ. Drying drum

1. Drying drum interior structure

Scientific and reasonable lifting board make material at perfect condition, good end sealing and heat preserving material outside drum body, and stainless heat preserving layer, all these enhance the thermal efficiency of drying drum.

The drying drum use high performance reducing motor and connected with supporting wheel is made of high temperature resistance nylon by universal coupling, and make drum running depending on friction. Equipped with elastic inflation gasket, it is can reduce driving wear, reduce noise and prolong service life.

2. Imported oil burner

Using high performance international well-know brand burner, this burner is made by using international latest flame technology. It can use different kinds of heavy oil and residual automatic switch of light or heavy oil wind and fuel ration. The advanced oil supplying system make heavy oil, residual oil fully atomization and burned. The fuel save ration can reach 7~15%, the flame regulating ration can reach 10:1.

The LCD display realize monitoring and modification for system parameters and fault alarming information. All the component control executing by PLC controller. IT is convenient and simple to operate. The burner has the following features comparing normal burner: advanced technology, reasonable structure, intelligent zed, high safety and performance. Low wearing, low noise and low pollution.

Ⅲ. Hot aggregate elevating, screening, storage and weighing system

1. Hot aggregate elevator

Hot aggregate elevator is chain type high efficiency elevator. The project using sleeve roller chain is made of alloy steel with features of steady running, small friction resistance, low noise, low fault rate, and long service life. At the same time, the chains have automatic tension device and equipped with anti-reversing electromagnetism reducing motor. All these guarantee safe, reliable and dfficient work of elevator.

Scientific and reasonable lifting board make material at perfect condition, good end sealing and heat preserving material outside drum body, and stainless heat preserving layer, all these enhance the thermal efficiency of drying drum.

The drying drum use high performance reducing motor and connected with supporting wheel is made of high temperature resistance nylon by universal coupling, And make drum running depending on friction. Equipped with elastic inflation gasket, it is can reduce driving wear, reduce noise and prolong service life.

2. Vibrating screen

It is equipped with high efficiency vibrating sieve, the fixing of screen use quick draw hook device which make it convenient and quick to replace the screen. The whole sieve is connected by anti-loose bolt which is firm and wears well. The vibrating sieve also use motor anti-phase brake device, it can avoid the jumping and abnormal movement. The sieve is enclosed in dust proof cover. There is charging port and dust collecting port on the dust proof cover, it is an ideal environmental device.

3. Hot aggregate bin and continuous type level indictor

The equipment has large volume hot aggregate bin which can guarantee the continuity of final products discharging, there is heat preserving layer outside bin which can reduce heat loss, save fuel consumption and reduce cost.There is contentious level indictor on each bin which can display material level changing condition continuously. There is thermal resistance thermo detector on sandstone scraps bin to test sandstone temperature. Every bin can realize aggregate accurate measuring. The special structure hopper gate avoid blockage. At the end of overflowing pipe and waste pipe, there are collecting hopper, pneumatic discharging, for the convenience of overflowing and waste material collecting and transporting.

4. The equipment has three measuring hoppers

a. Sandstone measuring hopper

Sandstone measuring hopper and special designed eccentricity hopper structure make the material hopper flexible and steady and avoid clamping. The pressure discharging pipeline avoid bad influence.

b. Powder weighing hopper

Power weighing hopper is equipped with pneumatic arch broken device, it is smooth and fast discharging. The special powder screw conveyor make the powder go into the mixer quickly and evenly, guarantee final products quality. The using of frequency control measuring screw conveyor guarantee high precision measuring.

c. Asphalt weighing hopper

Asphalt weighing hopper: use heat conducting oil for heating and heat preserving layer for preserving, it is covered with stainless steel and beautiful and energy saving, The special cone design make residual asphalt less, and with electromagnetism asphalt pump and one-way valve which enhance weighing precision. The asphalt injection use asphalt pump spraying type which can cover the aggregate surface evenly in mixing tank, enhance the final products quality and reduce the mixing time. The electrical control over weighing testing device avoid scale overflowing. The asphalt reducing, fluctuate measuring not only guarantee the weighing precision but also control asphalt and stone ration.

5. Weighing module

The weighing hopper use international well-known brand weighing module. The weighing module is equipped with high precision and reliability resistance type strain sensors, fully seal, it can fit any bad environment and do not influence the precision, with high reliability. The module is integrated modular structure, which can avoid level direction force influence and enhance the weighing precision efficiently.

Ⅳ. Mixing system

1. Mixer

The whole machine with a square frame has a feature of stable running, safety and good sight.

The scale board and blade head made by chrome and white abrade-bearing cast iron have long service life.

Using double cylinders controlled overturning type discharging gate, the hoppers have a advanced feature of short time discharging, good seal, easy open and close, avoid clamping stagnation.

The filling rate is no more than 60%, making the stones and asphalt mixing sufficiently, shorten the mixing time.

2. Reliable lubricating system

When adopting automatic lubricating system, using 380V mightiness motor can pump the lubricant to lubricating point, it can also use computer to set program, and pump the lubricant to lubricating point regularly, the manual lubricating system as stand by system, can keep the lubricating in time and reliably.

Ⅴ. Hot-conducting oil heating and asphalt supplying system

Adopting automatic horizontal type heat conducting oil heating system (modularization transportation and installation) and imported burners, it have function of auto-ignition, auto-monitoring function. The burner can change with conflagration small fire working according to the temperature of the heat conducting oil.

Ⅵ. Dust catching system

Gravity dust collector: the dust collecting effect can reach about 80%, the object is powder which is more than 75μm. All the powders of primary dust collecting can be sent into elevator by screw conveyor for recycling.

The loculose high pressure impulse dust collector: the bag material use NOMEX, United States, to guarantee the long time running under the high temperature. The service life is long and with good air permeability, the dust collecting object is dust who already finished primary dust collecting but diameter is less than 75μm. The bag control is connected with host machine and have temperature protecting system.

Ⅶ. Powder supply and recycling system

The reclaim powder after dust collecting is sent into powder recycling tank by three blades roots fan or screw conveyor or bucket type elevator, when do not use recycled powder, it can be exhausted by exhaust screw conveyor. The exhaust powder end is equipped with special design spraying dust proof screw conveyor and avoid dust flying.

The whole main frame under condition of minus press seal condition, avoid leakage, and improved the environment performance.

There is level indicator on the powder tank, on top of the tank there is dust collector, the air hammer under cone bottom of tank can avoid arching, the new powder tank and recycling tank top have over pressuring protection system and avoid breaking. The powder in new tank and recycling tank can be conveyed into powder weighing hopper by screw conveyor according to proportion.

Ⅷ. Pneumatic control system

The pneumatic system is equipped with imported and China famous brand air compressor with safe and reliable work. It use imported electromagnetic valve. The pneumatic valve use integration installation, this avoid dust and water entering and make sure long time operation.

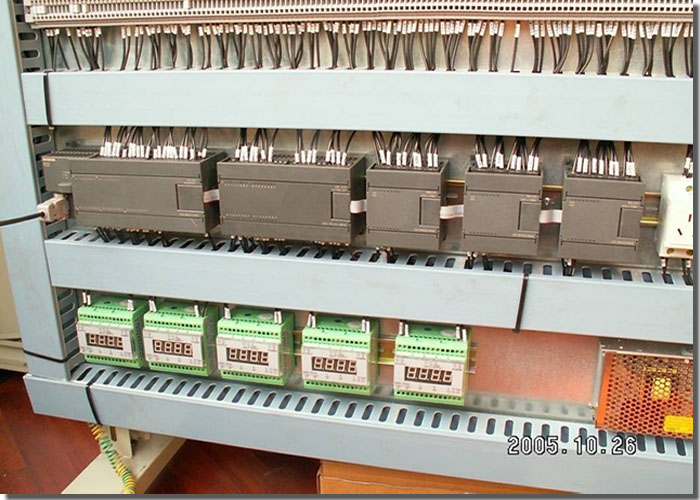

Ⅸ. Electrical control system and central control house

The control system use computer control, screen display and keyboard input. It is equipped with Siemens S7 300 high performance programmable controller, PROFINET general line control technology, distributing type I/O, use industrial Ethernet transferring and computer double screen control technology. The working performance is reliable, with convenient operation and direct display and high automation. The control house is commodious with air conditioner which makes male the operator feel comfortable.